Pipe Insulation shall be protected from damage due to sunlight, moisture, equipment maintenance, and wind. Protection shall, at minimum, include the following:

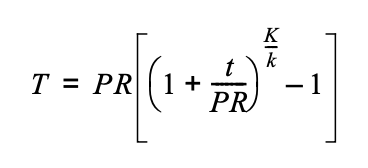

WHERE:

T = insulation thickness for material with conductivity K, inches.

PR = actual outside radius, inches.

t = Insulation thickness from Table 120.3-A, inches.

K = Conductivity of alternate material at the mean rating temperature indicated in Table 120.3-A for the applicable fluid temperature range, in Btu-inch per hour per square foot per °F.

k = The lower value of the conductivity range listed in Table 120.3-A for the applicable fluid temperature range, Btu-inch per hour per square foot per °F.

EXCEPTION 1 to Section 120.3: Factory-installed piping within space-conditioning equipment certified under Section 110.1 or 110.2.

EXCEPTION 2 to Section 120.3: Piping that conveys fluids with a design operating temperature range between 60°F and 105°F.

EXCEPTION 3 to Section 120.3: Where the heat gain or heat loss to or from piping without insulation will not increase building source energy use.

EXCEPTION 4 to Section 120.3: Piping that penetrates framing members shall not be required to have pipe insulation for the distance of the framing penetration. Metal piping that penetrates metal framing shall use grommets, plugs, wrapping or other insulating material to assure that no contact is made with the metal framing.

NOTE: Authority: Sections 25213, 25218, 25218.5, 25402 and 25402.1, Public Resources Code. Reference: Sections 25007, 25008, 25218.5, 25310, 25402, 25402.1, 25402.4, 25402.5, 25402.8, and 25943, Public Resources Code.